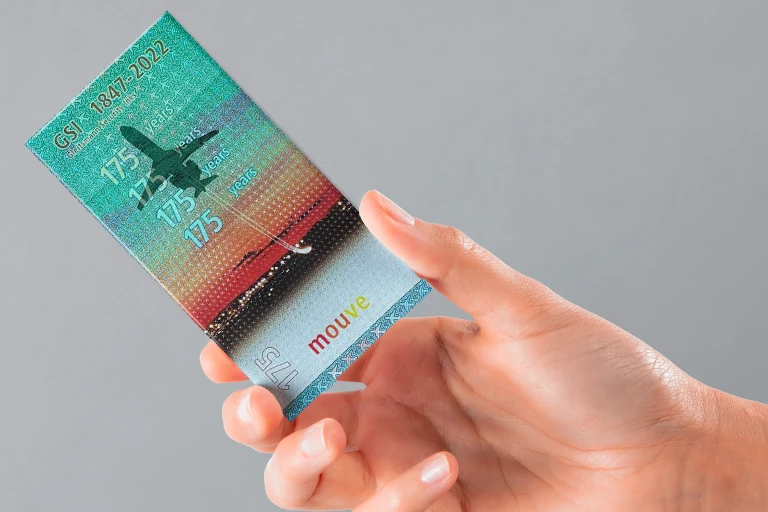

You are looking for a new, counterfeit-proof printed feature for a new banknote denomination or an upgrade of an existing design? Most likely it should be easy to check but difficult to forge? Then here’s your best solution: mouveINK

GSI has combined decades of experience in manufacturing security printing inks with the special know-how of its partner Leuchtstoffwerk Breitungen (LWB) from Thuringia, Germany. Launching the feature today to the international market, GSI offers decision makers at ministries and central banks a new option: A unique combination of two UV-colours together with a long-lasting durable green afterglow effect, not previously known to the industry. In addition, the patent-pending feature-ink combines well-established UV images with phosphorescence and a moving effect of interchanging colours. Furthermore, the feature can be checked by police officers, banknote experts and sorting machines using existing tools or sensors.

“We are extremely proud to reveal our first exclusive feature today, which is made 100% in Germany. Through the combination of proven security printing ink-technology with proprietary pigments from our partner LWB citizens and experts will enjoy the ease of use of mouveINK” said Ulrich Walter, Managing Director of GSI.

“LWB very much appreciates the cooperation with GSI. In the past we only developed proprietary security pigments for specific applications for just one respective customer. The partnership with GSI allows us a larger variety in security applications, thereby broadening our customer base” states Wolfgang Eisenberg, CEO of LWB.

The first generation of mouveINK will be available for intaglio and silk-screen printing. Both partners are already preparing more options for the future, such as colour-variants. For more information please refer to the product section at www.gsi-gmbh.com or scan the QR code.

About Leuchtstoffwerk Breitungen: Leuchtstoffwerk Breitungen GmbH (LWB) has decades of experience in development and manufacturing luminescent pigments for security and high-security applications. It offers security pigments with very high purity and reproducibility. LWB’s highest priority has been and will remain to be constant innovation and a very strong quality management in all its operations. LWB also manufactures luminescent pigments for special applications such as medical imaging, UV lamps, EL light sources and LEDs. It currently employs app. 25% of its people in development, quality assurance and application engineering.